UV Print & Laser Cut Acrylic Planar Service

Our Services

UV Printed Acrylic Planar

UV-printed acrylic planar combine contemporary design with vibrant, high-resolution imagery. These unique earrings are created using cutting-edge UV printing technology, resulting in stunning, durable designs that won't fade over time. With a flat, elegant profile, they are a stylish and lightweight accessory perfect for making a statement.

What is the Process of UV Printed Acrylic Planar?

UV printing on acrylic comprises several sequential stages:

1. Preparation: The acrylic surface undergoes thorough cleaning and preparation to optimize ink adhesion.

2. Printing: A UV-curable inkjet printer precisely transfers the digital design onto the acrylic surface.

3. Curing: The printed acrylic is subjected to UV light exposure, promptly solidifying the ink.

4. Post-printing process: Following printing, the acrylic is then send to the laser cutter for cutting down to the desired final product.

Materials that We Offered for UV Printed Acrylic Planar

We have various material options available for UV printing purposes for earrings. These include clear acrylic, white acrylic, color acrylics, and plywood. Choosing the best option depends on your preferences and how you want to showcase your artwork. Clear acrylic is the most affordable option among the acrylics and offers multiple printing methods, which we will discuss later. However, for white acrylic, color acrylic, and plywood, we only offer printing on the front surface. For more material option, please click

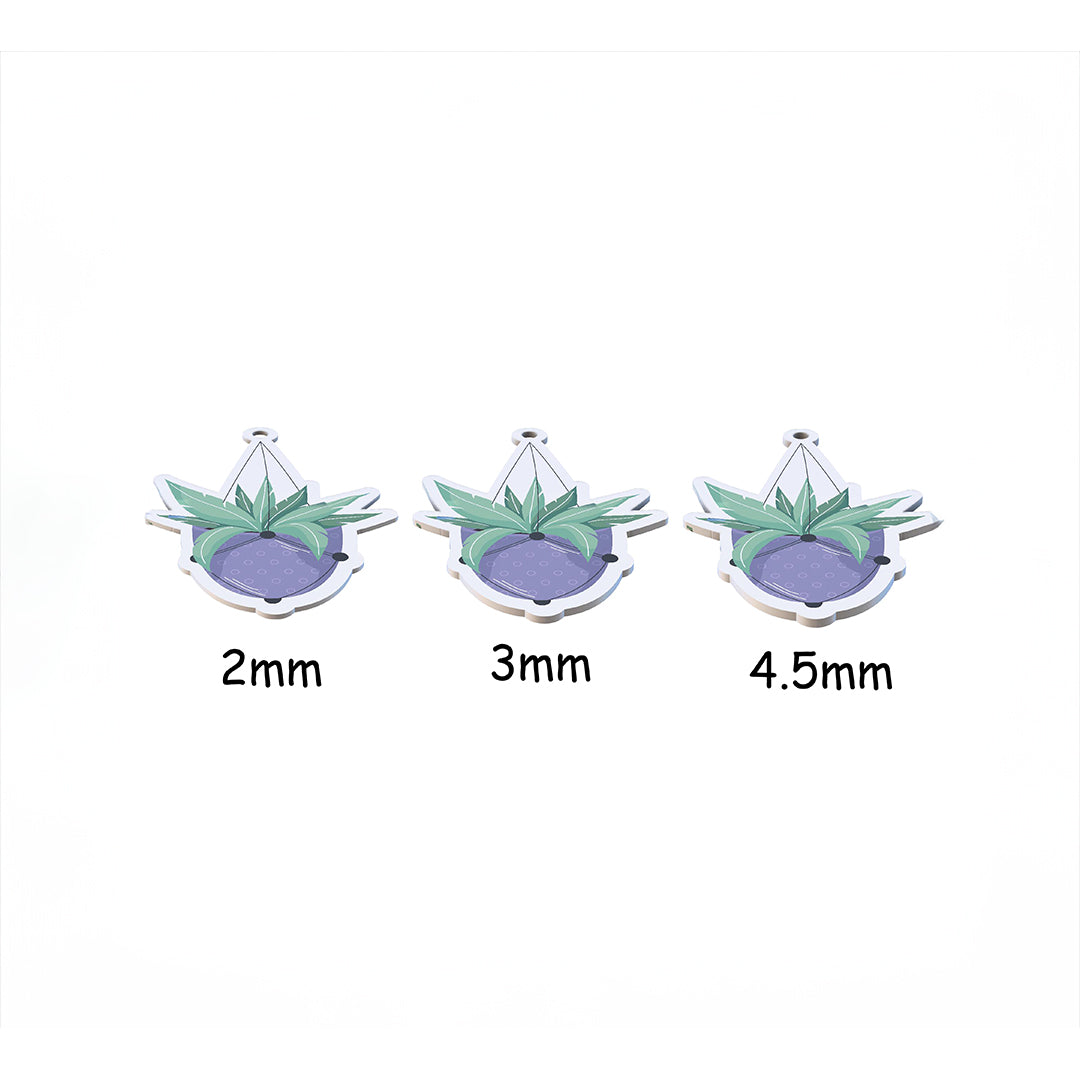

How to Choose Thickness for UV Printed Acrylic Planar?

Although our UV printer has the capability to print directly onto surfaces that are as thick as 50mm, it is not advisable to use such a thickness for earrings. Instead, what thickness should you consider? In the case of colored acrylic, the ideal thickness is 3mm because that is the only thickness available in the Australian market. For white and clear acrylics, we can offer 2mm, 3mm, and 4.5mm thicknesses. The weight of the earrings will be lighter with thinner acrylic. For plywood, we generally offer 3mm thickness. However, we can do custom request for thickness greater than 3mm. Ultimately, it depends on your preference for how you want your artwork presented in small earring pieces. From a cost perspective, thinner material is usually slighlty cheaper than thicker material.

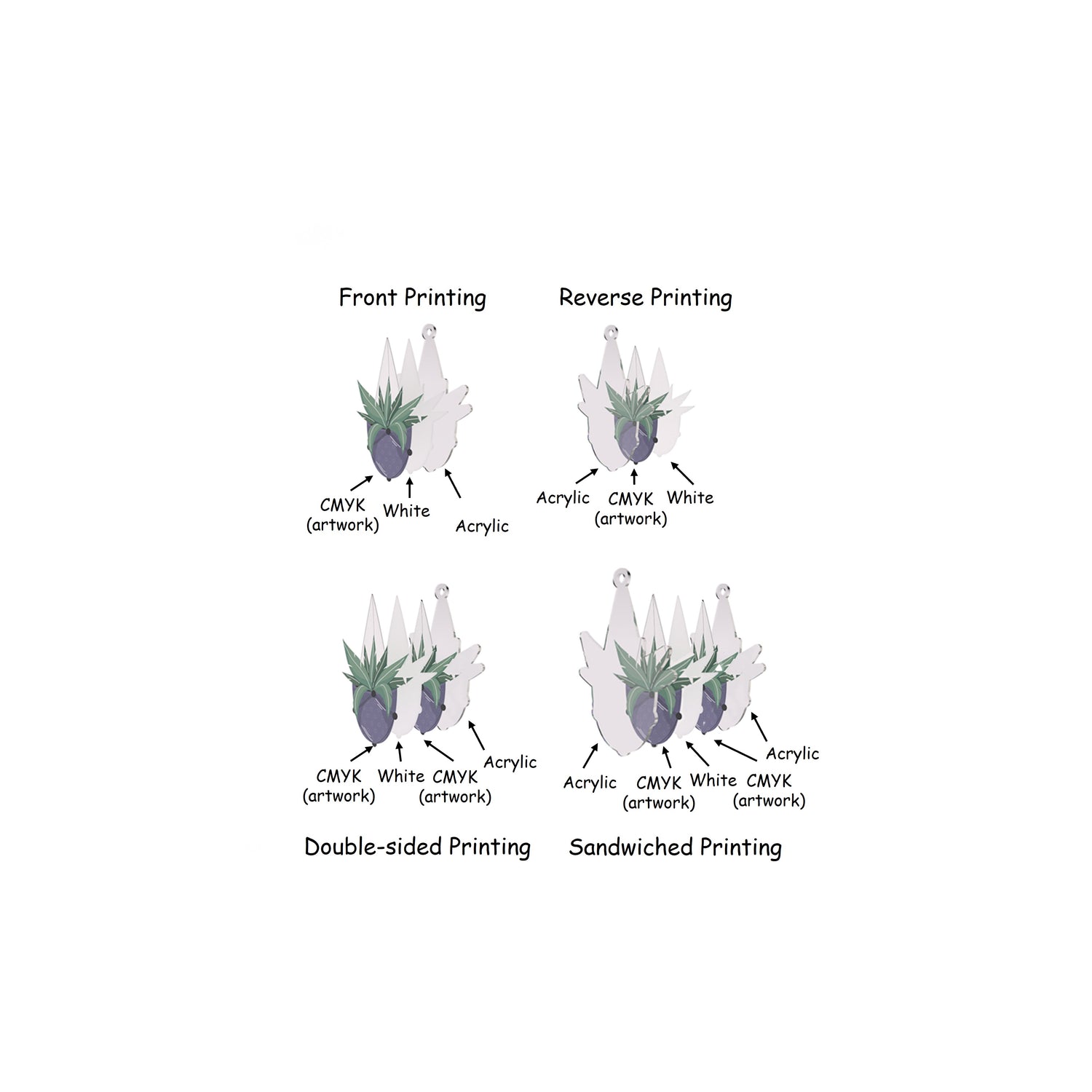

Methods of UV Printing

Front print, reverse print, and double-sided print differ in how the CMYK artwork print is applied to the material. With front print, the CMYK print is directly printed on top of the material.

When printing on white acrylic, white base ink is not needed as the material itself is white. However, for clear and colored acrylic, white base ink is used to enhance the vividness of the CMYK print. If a translucent effect is preferred on clear acrylic, customers can request for the white base ink to be omitted.

On the other hand, with reverse print, the CMYK print is applied behind the material and finished off with white base ink at the back.

Meanwhile, with double-sided print, the process involves a CMYK print on the front of the material followed by a layer of white ink, and another layer of CMYK print on top of the white ink. As a result, one side of the artwork will have a glossy effect due to the print behind the clear acrylic, while the other side will have a matte effect.

Recently, we have also introduced a brand new sandwiched printing method where the graphic artworks is in the middle of the acrylic, another level up experience from double-sided print. With this method, both side of the artworks are protected with the acrylic from scratches. This has opened up a lot more application to the production of merchandise items like keyrings, shoes charms, clogs charms, etc.

UV Varnish

UV varnish is a special type of varnish that is applied under UV light to create a vivid, luxurious, and tactile finish that looks more professional than non-UV varnishes. We can do both matt varnish as well as gloss varnish.

Varnish adds a layer of protection against daily wear and tear. However, whether it can protect against scratching depends on the tool used to scratch it. Mechanical abrasion can cause the ink to be scratched off of UV printed items.

For instance, when printing onto plywood, the ink soaks slightly into the plywood, making it difficult to remove the print without tearing off the surface of the ply. On the acrylic, the ink bonds extremely well with the primer we applied, but it can still be scratched off by metal tools like keys.

While it is not easy to do, there is still a risk of scratching. Hence, UV printing on acrylic is well-suited for earrings because they are not handled frequently and do not come into contact with hard or sharp objects.

If you request the print to be sandwiched print method, the application of varnish can be omitted as both side for this type of print have been protected by the acrylics.

Can you glue on the printed surface?

This is a good question. If you're working on a UV print studs earrings project, you'll need to attach the earring post to the back of the acrylic pieces using glue. Whether you need to be careful with the glue you use depends on whether you're using front print, reverse print or double-sided print. With front print, you don't need to worry too much about gluing the back since it's still the acrylic surface. However, with reverse or double-sided print, you need to be cautious about the type of glue you use. E6000 or similar adhesives are often used by earring makers, but they can be too aggressive and dissolve or affect the print if applied directly to the surface.

Through trial and error, we've found that using JustResin UV resin with a UV LED Nail Lamp can overcome this issue. Using an appropriate amount of the resin to glue the metal post to the acrylic has minimal impact on the printed surface. If you use too much, you run the risk of creating excess heat during the UV light curing process, which can cause cracks on the print surface. With some practice, you'll get the perfect result.

At present, we don't recommend other UV resin brands for this purpose, as each one has slightly different formulas and chemical components that may react with the printed surface. We'll keep you updated here if any other brands pass our testing for this purpose.

Printing Requirements

1. We can accept the following file format: .ai, .eps, .svg, .pdf and high resolution (300dpi at least) jpg.

*If you supply AI-generated images, the best resolution jpg is alright but contact us for more info on how to best produce the output file for this kind of artworks.*

2. The sheet size that we offered for printed earrings can in the following sizes: 600mmX300mm, 600mmX600mm or 900mmX600mm.

3. Fill in all the details according to the form below and submit a quote request.

Can I have more than one design in a sheet?

You are welcome to submit multiple designs. You can either pack the designs yourself according to the sheet sizes mentioned above, or we can assist you in packing them to fit the sheet. Once you accept the quote and complete the payment process, we will send you a design review for your final approval before we print and cut the printed earrings for you. Feel free to contact us if you have any question about the packing your artwork into the size of the sheet required.

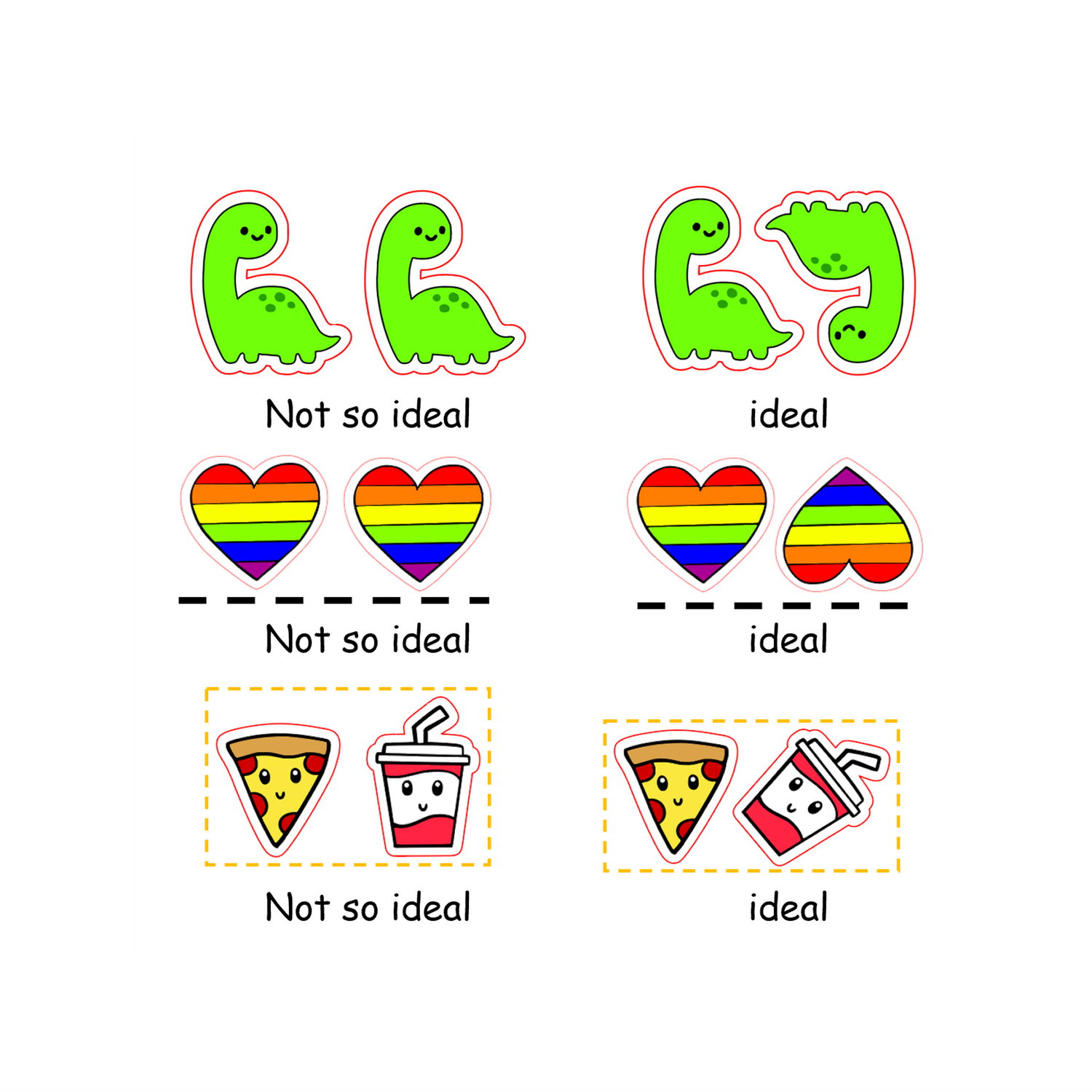

How many pieces will I get from one sheet?

The answer to this question depends on the size of your artwork plus outline and the sheet size you have chosen. It also depends on how you pack your artwork. To help illustrate on the packing, we have provided an image on the right.

Here is an idea of the quantities you can expect from a single sheet of 600mm x 300mm:

1. Artwork + outline with a 40mm diameter can yield approximately 98 pieces.

2. Artwork + outline with a 30mm diameter can yield approximately 162 pieces.

3. Artwork + outline with a 16mm diameter can yield approximately 260 pieces.

Please note that if your artwork is an irregular shape, the number of pieces you can get may be slightly more or less than the quantities mentioned above.